Looking to upgrade your home lighting to be more energy-efficient and long-lasting?

Retrofit LED recessed lighting could be the perfect solution for you.

In this article, we will discuss what retrofit LED recessed lighting is, the benefits of choosing this type of lighting, and the step-by-step process of installing it in your home.

We will also provide some tips for a successful installation and common mistakes to avoid.

Stay tuned to learn more about how to transform your space with retrofit LED recessed lighting.

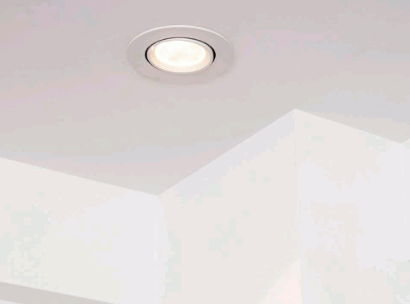

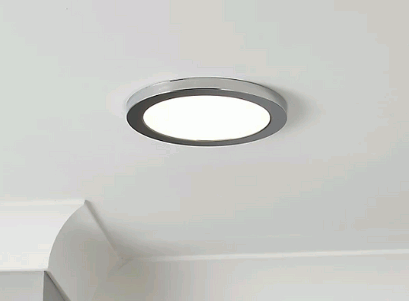

Retrofit LED recessed lighting involves upgrading existing light fittings with LED retrofit kits to provide efficient, modern lighting solutions for various interior spaces, including homes and offices.

LED retrofit kits typically include LED bulbs, a driver, and other necessary components, making it easy to convert older fittings to energy-efficient LEDs. On the other hand, recessed lights, also known as downlights, are versatile fittings that sit flush with the ceiling, offering a sleek and subtle lighting option. These retrofit solutions are not only cost-effective but also energy-efficient, reducing electricity bills and environmental impact. Whether in kitchens, living rooms, or commercial settings, retrofit LED recessed lighting adds a contemporary touch while enhancing visibility and ambiance.

Explore in-depth: Are LED Ceiling Lights Any Good

Selecting retrofit LED recessed lighting offers several benefits, including increased energy efficiency, longer lifespan of LED lights, and versatile design options suitable for various interior aesthetics.

Retrofit LED recessed lighting is highly energy-efficient, making it an eco-friendly choice for reducing electricity consumption and lowering utility bills.

LED lights are designed to consume significantly less electricity compared to traditional incandescent or fluorescent bulbs. These lights convert a greater percentage of energy into light rather than heat, resulting in lower energy waste. This improved efficiency not only translates to direct cost savings for the consumer but also has a positive impact on the environment by reducing overall electricity demand and greenhouse gas emissions.

One of the key benefits of retrofit LED recessed lighting is the longevity of LED lights, which significantly outlast traditional lighting options.

LED lights used with retrofit kits have an extended lifespan that can reach up to 50,000 hours or more, compared to the average lifespan of incandescent bulbs which is around 1,000 hours. This durability means that once installed, LED lights require minimal replacements, reducing the need for frequent maintenance and lowering overall operating costs. The longevity of these lights not only ensures consistent illumination but also contributes to environmental sustainability by reducing the number of disposed bulbs that end up in landfills.

Retrofit LED recessed lighting offers versatility in design, allowing for various downlight styles that can seamlessly blend with different interior settings.

One of the key features of retrofit LED recessed lighting is its ability to offer a wide range of downlight styles that cater to different aesthetic preferences and lighting needs. Whether you prefer a sleek and modern look or a more traditional design, there are options available to suit your desired ambiance.

For contemporary spaces, a timeless downlight style can provide a clean and minimalist appearance, seamlessly integrating into the ceiling for a seamless look. On the other hand, adjustable gimbal downlights offer flexibility in directing the light beam, making them ideal for highlighting specific areas or artworks within a room.

Installing retrofit LED recessed lighting is a straightforward DIY project that can be accomplished by following a step-by-step tutorial, ensuring a successful upgrade with LED retrofit kits.

Having all the essential items at hand before beginning the installation is crucial to ensure a smooth and efficient process. Along with the mentioned tools, you will also need a ladder for reaching the ceiling, wire strippers, a voltage tester, and a screwdriver.

Make sure to check that you have the correct size and type of LED retrofit kit for your recessed lighting fixtures to avoid any compatibility issues during the installation.

Before beginning any electrical work, it's crucial to switch off the power to the existing light fitting to ensure safety during the installation process.

Taking these precautions significantly reduces the risk of injury or damage.

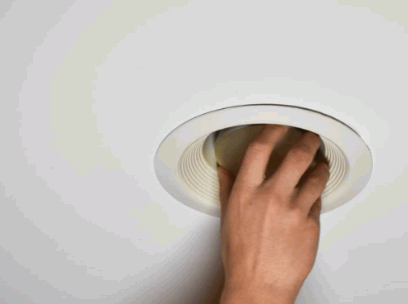

Carefully remove the existing light fitting by following the steps outlined in the tutorial, ensuring not to damage the ceiling or surrounding areas.

Prepare the ceiling for the installation of the new downlights by ensuring the housing and brackets are properly positioned and secured.

Once the housing and brackets are checked, the next crucial step is to identify the optimal placement for the downlights. This involves considering the room layout, furniture arrangement, and the desired lighting effect. Proper positioning is key to achieving an even distribution of light and avoiding glare or shadows. It is recommended to create a layout plan to mark the exact spots where the downlights will be installed. Double-check the ceiling material to determine if any additional support is needed for secure installation.

Connect the wiring for the retrofit LED recessed light, ensuring all electrical connections are secure and comply with safety standards.

It is essential to follow these steps diligently to avoid any electrical hazards and ensure a properly functioning lighting system.

Install the retrofit LED recessed light by carefully positioning it into the ceiling and securing it with torsion springs, clips, or c-clips as needed.

After confirming the correct placement of the light, gently rotate the torsion springs in a clockwise motion to lock the fitting securely in place. Ensure that the clips or c-clips are properly aligned with the designated slots on the light housing.

Once everything is securely connected, test the light to ensure it functions properly before fully completing the installation. Take care to avoid over-tightening the torsion springs, as this may cause damage to the ceiling or the fitting.

After installation, test the LED lights to ensure they are functioning properly and make any necessary adjustments as per the tutorial.

Testing the lights post-installation is crucial to guarantee optimal performance and safety. Start by checking each light fitting individually, ensuring they are securely in place and connected properly. Then, switch on the lights to observe if they illuminate as expected, without flickering or dimming. If any issues arise, consult the instructional manual for troubleshooting steps. Adjust the positioning or angle of the lights if needed to achieve the desired lighting effect. Remember that thorough testing ensures a seamless and enjoyable lighting experience.

To ensure a smooth and efficient installation of retrofit LED recessed lighting, consider these helpful tips that can guide you through the DIY process and help avoid common pitfalls.

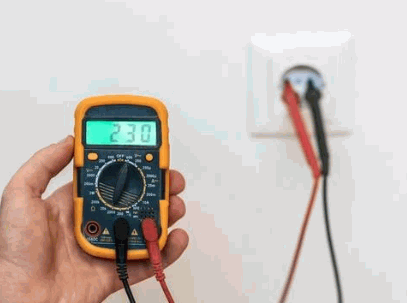

Using a voltage tester is crucial to ensure electrical safety during the installation of retrofit LED recessed lighting.

Before starting any electrical work, always remember safety first. One important step in this process is checking for live wires using a voltage tester.

Always follow the manufacturer's instructions provided with your LED retrofit kits to ensure a correct and safe installation.

These guides are carefully crafted to streamline the process and prevent any potential hazards that may arise from incorrect installation methods. They typically include step-by-step procedures, recommended tools, and safety precautions to be followed during the setup. Adhering to these instructions not only guarantees efficient performance but also extends the lifespan of your LED lighting system.

Some common steps covered in the guide may include identifying the right fixtures for your space, ensuring proper wiring connections, and testing the lights post-installation. They often emphasize the significance of turning off the power supply before commencing any work and handling the components with care to avoid damage.

If you are unsure about handling electrical wiring or the installation process, consider hiring a professional to ensure the job is done safely and correctly.

Electrical wiring can be a complex and potentially hazardous task that requires specific knowledge and skills to execute properly. A professional electrician possesses the expertise to navigate the intricacies of electrical systems, ensuring that all connections are secure, circuits are correctly set up, and safety measures are implemented.

Professionals are equipped with the necessary tools and equipment to conduct the installation efficiently and effectively. They can also identify and troubleshoot any potential issues that may arise during the process, providing a seamless and reliable solution. By hiring a professional, you not only save time and effort but also minimise the risk of accidents or errors.

When installing retrofit LED recessed lighting, it's important to be aware of common mistakes that can hinder the process and affect the final outcome, especially for DIY enthusiasts.

One of the most critical mistakes is not turning off the power before starting the installation, which poses significant safety risks.

Inadequately shutting off the power supply can result in electrical shocks, fires, or even fatalities. It's essential to locate the main circuit breaker or fuse box and switch off the power to the specific area where the installation will take place. This step is vital in preventing accidental contact with live wires.

Once the power is turned off, double-check by using a non-contact voltage tester to ensure there is no electricity running through the circuits. These testers are affordable and can save lives by indicating the presence of current.

It's advisable to inform others in the household or workplace about the power shutdown to avoid any accidental reconnection. Taking these precautions will help create a safe working environment during the installation process.

Incorrect wiring can lead to malfunctioning lights and potential safety hazards, making it essential to follow proper wiring techniques during installation.

Aside from safety concerns, correct wiring also ensures optimal performance and efficiency of electrical systems. One common mistake is not securing connections properly, leading to loose wires and potential short circuits.

Regular testing using a multimeter can help confirm that all connections are functioning as they should. Remember, taking the time to wire things correctly can save you from headaches down the road.

Not measuring the ceiling space properly for downlights can result in improper fitting and alignment issues during the installation.

Accurate measurements are crucial to ensure that the downlights fit seamlessly into the ceiling, enhancing the overall aesthetics of the room. To measure the ceiling space correctly, start by determining the placement of each downlight. Use a measuring tape to find the exact distances between each intended fixture location. It's also important to account for any obstructions or existing fixtures that may impact the installation process.

Investing in tools like a laser level or a stud finder can greatly assist in achieving precise measurements. A laser level helps you mark accurate positions on the ceiling, while a stud finder can identify any structural elements that may affect the installation.

LED ceiling lights have become increasingly popular in recent years due to their energy efficiency, long lifespan, and versatility in design.

We will explore how LED ceiling lights work, their advantages, and disadvantages, and how they compare to other types of lighting. We will also provide tips on what to consider before purchasing LED ceiling lights, such as room size, color temperature, dimming options, and brand quality.

Learn more about the pros and cons of using LED ceiling lights in your home or office.

LED ceiling lights are energy-efficient lighting solutions designed to fit various ceiling light fittings, making them ideal for rooms with low ceilings. They utilise LED bulbs, which consume less energy compared to traditional lighting options, providing long-lasting and sustainable illumination.

There are several types of LED ceiling lights available, including flush mount, semi-flush mount, and recessed options, each offering a different aesthetic and level of brightness. These lights are versatile and come in various shapes, sizes, and designs to suit different room heights and styles.

The energy efficiency of LED ceiling lights not only reduces electricity bills but also contributes to environmental sustainability by decreasing carbon footprint. This eco-friendly feature makes them a popular choice for modern homes seeking to minimise energy consumption.

Find out more: Is LED Lighting Sustainable

LED ceiling lights work by using integrated LEDs that emit light when an electrical current passes through them, and these can be adjusted to different colour temperatures based on the Kelvin Level.

Integrated LEDs are essentially small semiconductors arranged in a circuit on the light fitting's board. When electricity flows through the diode, it causes electrons to release energy in the form of photons, creating visible light. By adjusting the Kelvin Level, you can fine-tune the warmth or coolness of the light produced. This flexibility not only allows for customisation based on preferences but also plays a crucial role in setting the ambience of a space.

The advantages of using LED ceiling lights are numerous, ranging from being energy efficient to having a long lifespan, making them a superior choice compared to traditional lighting methods.

One of the primary benefits of LED ceiling lights is their energy efficiency, as they consume significantly less power compared to traditional halogen bulbs.

By utilising LED ceiling lights, households and businesses can experience a noticeable decrease in their electricity bills over time. This is due to the fact that LEDs convert a higher percentage of energy into light rather than heat, unlike halogen bulbs which produce more heat. As a result, the overall energy consumption is lower, translating to cost savings. The reduced energy usage of LED lights contributes to a smaller carbon footprint, making them a more environmentally friendly lighting option compared to traditional alternatives.

LED ceiling lights are known for their long lifespan, often lasting up to 50,000 hours, which significantly reduces the need for frequent replacements.

This longevity not only provides consistent lighting for longer periods but also contributes to the durability and cost-effectiveness of these lighting fittings. With typical lifespans averaging around 15-20 years of regular use, LED bulbs offer substantial savings in the long term. The reduced frequency of replacements not only saves money on new bulbs but also lowers maintenance costs over time. This makes them a practical choice for both residential and commercial settings, allowing users to enjoy reliable lighting without worrying about frequent changes.

The durability of LED ceiling lights, including models like the Morris Slimline LED Batten Tube Light, makes them a reliable and robust option for various lighting needs.

LED ceiling lights are typically constructed using high-quality materials such as aluminium and polycarbonate, which not only enhance their longevity but also ensure efficient heat dissipation. This construction plays a crucial role in preventing overheating and maintaining the performance of the light over time. The Morris Slimline LED Batten Tube Light, for example, is known for its sturdy build and excellent heat management capabilities.

LED ceiling lights offer versatility in design, accommodating various ceiling light fittings and styles such as rectangular LED panels.

In terms of shapes, LED ceiling lights are available in options ranging from round and square to more intricate geometric designs, allowing you to choose the perfect shape to complement your space.

These lights come in a variety of sizes, from compact and discreet options for smaller rooms to larger statement pieces that can become a focal point in a spacious area.

The fitting types for LED ceiling lights are also diverse, with recessed, surface-mounted, and pendant fittings among the popular choices, offering flexibility in installation depending on your ceiling structure and design preferences.

LED ceiling lights provide instant brightness without the flickering often associated with other types of lighting.

Thanks to the advanced LED technology, these ceiling lights are able to achieve immediate full light output, making them ideal for settings where instant illumination is crucial, such as offices, kitchens, and bathrooms. The absence of flickering not only enhances the aesthetics of the space but also brings significant benefits to eye health and overall comfort.

By eliminating flickering, LED ceiling lights reduce eye strain and fatigue, creating a more pleasant and productive environment for tasks that require focus and concentration. This stability in lighting can also contribute to a sense of well-being and can be particularly beneficial for individuals sensitive to light changes.

Whilst the initial investment might be higher, LED ceiling lights are cost-effective in the long run due to their energy efficiency and reduced maintenance costs.

LED lights consume significantly less electricity compared to traditional lighting options, resulting in substantial savings on energy bills over time. Their longer lifespan means less frequent replacements, reducing overall maintenance costs. This combination of energy efficiency and durability makes them a wise choice for both residential and commercial spaces, offering a notable return on investment in terms of financial savings and environmental impact.

Despite their many advantages, LED ceiling lights also come with certain disadvantages, such as a higher initial cost, limited color options, and potential glare problems.

One of the main disadvantages of LED ceiling lights is their higher upfront cost compared to traditional lighting options.

LED ceiling lights tend to have a higher initial price due to the advanced technology and materials used in their production, such as semiconductor chips and heat sinks.

This initial investment is often offset by the significant savings in energy costs over the lifetime of the LED lights. LEDs are much more energy-efficient than traditional incandescent or fluorescent bulbs, consuming up to 80% less energy.

Moreover, LED lights have a longer lifespan compared to traditional lighting sources, reducing the need for frequent replacements and maintenance, which can further cut down on long-term costs.

When comparing the total cost of ownership, including energy consumption and maintenance expenses, LED ceiling lights prove to be a more cost-effective and sustainable lighting solution in the long run.

LED ceiling lights may have limited colour options, primarily offering shades of warm white and cool white.

Despite these constraints, one notable feature of LED lighting technology is the ability to adjust the colour temperature of the light emitted. This allows users to switch between warmer, more yellow tones and cooler, bluer hues, providing a certain degree of versatility within the limited colour spectrum.

On the contrary, traditional incandescent and fluorescent lights offer a wider array of colours, with options ranging from soft yellows to bright blues and everything in between. This variation makes them a popular choice for those seeking more eclectic lighting arrangements.

Potential glare can be an issue with LED ceiling lights, especially if the integrated LEDs are not properly diffused.

Glare in LED ceiling lights primarily stems from the intense brightness of the light source itself, which can cause discomfort and reduce visibility. The direct exposure to the uncovered LEDs can create harsh contrasts and make it challenging to focus on tasks. Designers have found that incorporating diffusers in the light fittings can help soften the light output, dispersing it more evenly throughout the space.

Furthermore, proper installation of the ceiling lights plays a crucial role in minimising glare. Mounting the fittings at the correct height and angle can significantly reduce direct eye contact with the LEDs, thus reducing the potential for glare. Product selection is also essential, with manufacturers offering a variety of diffuser options to suit different preferences and needs. By choosing fittings with appropriate diffusing mechanisms, individuals can enjoy the benefits of LED lighting without the drawbacks of glare.

When comparing LED ceiling lights to other types of lighting like halogen bulbs and fluorescent lights, it becomes evident that LEDs are more energy efficient and have a longer lifespan.

Compared to incandescent lights, LED ceiling lights are significantly more energy efficient and have a much longer lifespan.

LED lights consume up to 80% less energy compared to traditional incandescent bulbs, making them an eco-friendly choice for lighting fittings. LEDs can last up to 25 times longer than incandescent lights, which means fewer replacements are needed, reducing both maintenance costs and environmental impact.

In terms of overall efficiency, LED ceiling lights outperform incandescent lights by providing brighter illumination using less energy, ultimately leading to lower electricity bills. The switch from incandescent to LED ceiling lights not only benefits the environment but also saves money in the long term.

LED ceiling lights, such as the Morris Slimline LED Batten Tube Light, offer several advantages over fluorescent lights, including better energy efficiency and longer lifespan.

LED lights are known for their superior energy efficiency, consuming up to 80% less energy than traditional fluorescent lights. This not only reduces electricity bills but also contributes to a greener environment by lowering carbon footprint.

In terms of maintenance, LED ceiling lights like the Morris Slimline require minimal upkeep compared to fluorescent lights which often need frequent bulb replacements. LED lights do not contain harmful mercury like fluorescent tubes, making them less harmful to the environment when disposed of.

Before buying LED ceiling lights, it's important to consider factors such as room size, colour temperature preferences, available dimming options, and the overall quality of the product.

The size and layout of the room play a crucial role in determining the type and number of LED ceiling lights and ceiling light fittings needed for optimal illumination.

When evaluating room dimensions for LED ceiling lights, it's essential to consider the height of the ceiling to determine the appropriate mounting options. Proper positioning of the lights can enhance the overall aesthetic of the room while providing adequate brightness. Additionally, evaluating the room's function helps in deciding the type of lighting required; for instance, task lighting for work areas or ambient lighting for relaxation spaces. To achieve a balanced lighting coverage, strategic placement of LED ceiling lights around the room's perimeter or in the center can create a harmonious lighting atmosphere.

The color temperature of LED ceiling lights, measured in Kelvin Level, can range from warm white to cool white, affecting the ambiance of the space.

Warm white lighting with a color temperature of around 2700-3000K creates a cozy and intimate atmosphere, perfect for bedrooms, living rooms, and dining areas.

On the other hand, cool white lighting ranging from 3500-4500K is ideal for task-oriented spaces like kitchens, offices, and workrooms, as it promotes alertness and productivity.

For spaces requiring a balance between warmth and functionality, a neutral white light around 3500-4000K works well in areas like hallways and bathrooms. It provides a crisp, clean light without being too harsh or too dull.

Dimming options are an important feature of LED ceiling lights, allowing users to adjust the brightness levels of integrated LEDs according to their needs.

LED ceiling lights equipped with dimming capabilities offer numerous benefits to users. One of the key advantages is the ability to create different ambiences in a room, from bright and energising to soft and cosy, with just a simple adjustment of the dimmer switch.

When considering compatibility with dimmer switches, it is essential to choose LED lights that are specifically labelled as 'dimmable.' Not all LED lights are designed to work with dimmers, so selecting the right products ensures smooth operation and longevity.

When purchasing LED ceiling lights, considering the brand and quality is essential, with reputable brands like Tom Dixon, DM Lights, and Heal’s offering reliable options.

Opting for high-quality LED ceiling lights from trusted brands not only ensures longevity but also guarantees superior performance. Brands like Tom Dixon, DM Lights, and Heal’s have established themselves as industry leaders due to their commitment to producing top-notch lighting solutions.

By investing in reputable brands, consumers can be confident in the durability and efficiency of their LED ceiling lights, contributing to a more sustainable and cost-effective lighting solution for their spaces.

LED lighting has revolutionized the way we illuminate our homes and businesses. From energy efficiency to environmental impacts, LED lighting offers a range of benefits.

This article explores the inner workings of LED lighting, its advantages, and its contribution to sustainability. We will also discuss potential drawbacks and provide tips for consumers to make sustainable choices.

Join us as we delve into the world of LED lighting and discover how it can help create a more sustainable future.

LED lighting, also known as Light-Emitting Diodes, refers to a form of artificial lighting that utilises semiconductor technology to convert electricity into light efficiently.

LED lighting technology traces its roots back to the early 1960s when red LEDs were first developed. Over time, advancements in LED technology expanded the colour range and brightness levels, leading to their widespread adoption in various applications.

Compared to traditional light sources like incandescent or fluorescent bulbs, LEDs offer significant benefits. They consume substantially less energy, have a longer lifespan, emit little heat, and are more durable. This energy efficiency has led to their popularity in residential, commercial, and industrial settings around the world.

LED lighting works by passing an electrical current through a semiconductor material, which then emits light through the principle of electroluminescence.

In contrast to traditional incandescent bulbs that produce light by heating a wire filament until it glows, and CFLs which use electricity to excite mercury vapor, LEDs generate light when electrons recombine with electron holes within the semiconductor material, releasing energy in the form of photons. This direct conversion of electrical energy into light results in LEDs being highly efficient, emitting very little heat compared to other lighting technologies.

Dig deeper: How To Install Retrofit LED Recessed Lighting

LED lighting offers numerous benefits over traditional lighting solutions, including superior luminous efficacy, greater energy efficiency, longer service life, and versatility in applications.

One of the primary advantages of LED lights is their remarkable energy efficiency, which translates into significant energy savings and a reduction in global electricity consumption.

LED lights stand out for their ability to convert a higher percentage of energy into light, leading to less wasted electricity and lower utility bills for households and businesses. This efficiency is showcased by the fact that traditional incandescent bulbs waste about 90% of their energy as heat, while LEDs waste only about 10%.

Compared to compact fluorescent lamps (CFLs), LEDs also come out on top, consuming up to 75% less energy. This technology has made significant strides in recent years, contributing to a substantial decrease in global energy consumption.

LED lights boast a significantly longer lifespan compared to traditional lighting solutions, which results in lower maintenance costs and enhanced durability over time.

For instance, while incandescent bulbs typically last around 1,000 hours and CFL bulbs about 8,000 hours, LED lights can shine for an impressive 25,000 to 50,000 hours. This means that LED lights can outlast incandescent bulbs by 25 to 50 times and CFL bulbs by over 3 to 6 times. Due to this prolonged lifespan, businesses and households benefit from reduced frequency of replacements, cutting down on both time and expenses associated with maintenance.

LED lights are known for their exceptional durability, which is partly due to their ability to manage thermal energy efficiently and their robust construction.

Efficient thermal management is crucial for LED lights as it helps dissipate heat effectively, preventing overheating and prolonging the lifespan of the components. In addition, high-quality materials used in manufacturing enhance the resilience of the lights, making them more resistant to environmental factors and wear and tear. These factors combined result in reduced maintenance requirements and longer service life, making LED lights a cost-effective and reliable lighting solution for various applications.

The versatility of LED lighting allows it to be used in a wide range of applications, from residential use to illuminating large sports venues and stadiums.

LED lighting has become increasingly popular in residential settings due to its energy efficiency, longevity, and customisable features. Homeowners can benefit from the variety of LED fixtures available, such as sleek recessed lighting, stylish pendant lights, and innovative smart bulbs that can be controlled remotely.

In commercial spaces, LED lighting is favoured for its ability to enhance the atmosphere, improve productivity, and reduce energy costs. Offices, retail stores, and restaurants utilise LED track lighting, panel lights, and accent lighting to create welcoming environments for customers and employees.

The specialised applications of LED lighting in sports venues are remarkable. LED floodlights and stadium lighting solutions offer superior brightness, colour rendering, and durability, ensuring optimal visibility for players and spectators during sporting events such as football matches and concerts.

LED lighting has a profound impact on the environment, promoting sustainability by reducing energy consumption, decreasing light pollution, and minimising the use of hazardous materials.

LED lighting dramatically reduces energy consumption compared to traditional light sources, leading to substantial savings in global electricity consumption.

One of the key reasons for the significant energy savings achieved by LED lighting is its remarkable efficiency. LEDs convert a higher percentage of electricity into light, generating less heat in the process compared to incandescent or fluorescent bulbs.

This higher efficiency translates into lower electricity usage, which has a direct impact on overall energy consumption. In fact, statistics reveal that lighting accounts for around 15% of global electricity consumption, with traditional lighting technologies contributing significantly to this figure.

By consuming less energy, LED lighting contributes to a significant reduction in carbon footprint and greenhouse gas emissions.

LED lighting is more energy-efficient compared to traditional incandescent or fluorescent lighting options, as it converts a higher percentage of energy into light rather than heat. This increased efficiency translates into lower energy consumption, thus decreasing the amount of carbon dioxide and other greenhouse gases released into the atmosphere. In fact, statistics show that LED technology can reduce greenhouse gas emissions by up to 70% compared to conventional lighting sources, making it a key player in achieving global sustainability targets for carbon emission reductions.

LED lights do not contain toxic elements such as mercury, which are prevalent in other types of lighting, making them a safer option for the environment.

On the other hand, traditional incandescent lights and CFLs do contain hazardous substances like mercury, lead, and other toxic materials. When these conventional bulbs are disposed of improperly, these toxic elements can leach into the soil and water sources, posing serious environmental and health risks.

LED lighting contributes to sustainability through energy-efficient performance, reduced waste production, improved air quality, and lower carbon emissions.

LED lighting plays a critical role in energy conservation due to its high luminaire efficiency and energy-efficient performance.

When compared to traditional lighting technologies, LED lighting stands out for its ability to significantly reduce energy consumption while still providing ample illumination. The luminaire efficiency of LEDs ensures that a larger percentage of the electricity used is converted into visible light, resulting in lower energy wastage. This not only helps in cutting down electricity bills for households and businesses but also contributes to a greener environment by reducing carbon emissions. With advancements in LED technology, the lifespan of LED bulbs has increased, further enhancing their sustainability and energy-saving benefits.

The longer lifespan of LED lights significantly reduces waste production and facilitates easier recycling and disposal processes.

LED lights, owing to their durability, require less frequent replacement compared to traditional incandescent or fluorescent bulbs, ultimately resulting in less waste being generated. This reduction in waste not only benefits the environment but also minimizes the resources needed for manufacturing new bulbs.

Regarding recycling, LEDs are more environmentally friendly than other lighting types. The materials used in LEDs, such as aluminium and plastic, are highly recyclable, making it easier to repurpose components and reduce overall waste sent to landfills.

Using LED lights can lead to improved air quality by reducing the release of toxic elements into the environment.

When compared to traditional lighting sources such as incandescent or fluorescent bulbs, LEDs do not contain harmful substances like mercury, lead, or other toxic chemicals. This absence of hazardous materials in LEDs means that there is a significantly lower risk of environmental contamination through air pollution when these lights are disposed of or broken.

LEDs are not only environmentally friendly during operation but also have a reduced carbon footprint due to their energy efficiency. This means that the overall environmental impact of LED lights is much lower compared to traditional lighting options, making them a sustainable choice for both indoor and outdoor illumination.

LED lighting contributes to reduced carbon emissions, aligning with global sustainability targets and energy savings initiatives.

LED lighting technology is recognised for its energy efficiency and minimal environmental impact. By replacing traditional lighting sources with LEDs, significant reductions in energy consumption and greenhouse gas emissions are achievable. This shift towards LED lighting supports the United Nations Global Goals, which aim to combat climate change and ensure sustainable energy for all. Through enhanced energy efficiency and longer lifespan, LED lighting solutions play a vital role in achieving a more sustainable future.

Despite its many advantages, LED lighting does have potential drawbacks, including higher upfront costs, potential blue light hazards, and limited color options.

One of the main drawbacks of LED lighting is its higher upfront cost compared to traditional lighting options, although this is often offset by long-term energy savings and reduced maintenance costs.

Whilst the initial investment in LED lighting fixtures may seem steep, it's important to consider the substantial energy efficiency benefits that these modern solutions offer. LED lights consume far less electricity compared to incandescent or fluorescent options, resulting in significant cost savings on utility bills over time.

The longevity and durability of LED lights mean that they require less frequent replacement, reducing the need for maintenance and replacement expenditures in the long run.

LED lights emit blue light, which has been linked to potential health hazards such as eye strain and disruptions to circadian rhythms, raising concerns for global health.

Studies have shown that prolonged exposure to blue light can lead to digital eye strain, characterised by symptoms such as dry eyes, headaches, and blurry vision. The blue light emitted from LEDs can interfere with the production of melatonin, the hormone responsible for regulating sleep-wake cycles, potentially causing sleep disturbances and insomnia.

Researchers suggest that limiting screen time, using blue light filtering glasses, and adjusting the colour temperature of devices can help mitigate the negative effects of blue light exposure. Incorporating more warm-coloured lighting in the evening and establishing a bedtime routine free from electronic devices can aid in restoring disrupted circadian rhythms.

Whilst LED lighting offers many benefits, it has a limited range of colour options, which can affect visibility and suitability for certain lighting applications.

Compared to traditional incandescent bulbs or fluorescent lights, LED technology falls short in terms of the variety of colours it can produce. Incandescent bulbs, for example, can emit a warm, yellowish glow, while fluorescents can offer a cooler, bluish light. This broader spectrum allows for more versatility in creating different atmospheres and meeting specific lighting needs.

LED's limited colour choices, typically including white, warm white, and a few other standard colours, may not be ideal for environments where vibrant or specific hues are required. This can be a drawback in settings where colour accuracy or the ability to create different moods through lighting is crucial.

Consumers can make sustainable choices with LED lighting by selecting energy-efficient products, such as those from LED iBond and Everly, and by following best practices for installation and use.

When choosing LED lighting, look for products with high energy efficiency ratings, like Energy Star certification. These LEDs consume less power whilst providing optimal brightness, ensuring long-lasting performance. Energy savings achieved through LEDs can significantly reduce electricity costs over time. Consider the colour temperature and lumens output to match the lighting needs of each room or space.

Interested in adding a touch of elegance and sophistication to your space?

Venetian plastering might just be the perfect solution for you.

In this article, we will explore what Venetian plastering is, why you should choose it, and the factors that can affect its cost.

From the type of plaster used to the size of the area and the complexity of the design, we will break down the average cost of Venetian plastering and provide tips on how to find a reliable contractor and save money on your project.

Don't miss out on this valuable information!

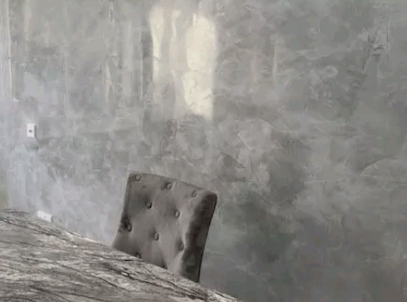

Venetian plastering is a decorative finish for walls, ceilings, and sometimes floors, originating from Ancient Greece and Egypt. It involves applying multiple layers of lime putty mixed with marble granules or other aggregates to create a smooth, polished marble effect. The final touch often includes a wax coat to enhance the finish, making it a popular choice for those seeking a luxurious and elegant surface.

This ancient technique has been passed down through generations and is renowned for its timeless beauty and durability. Traditionally, Venetian plaster was used in grand European palaces and villas to emulate the look of real marble without the weight and cost. The materials used in Venetian plastering, such as slaked lime, allow for a breathable finish that is ideal for both interior and exterior applications. The application process requires skill and precision, as each layer must be applied and polished meticulously to achieve the desired depth and sheen.

Uncover more: What Is Skimming Plaster

Choosing Venetian plastering for your space not only adds a touch of elegance but also offers unparalleled durability and a unique aesthetic appeal.

The use of natural materials in Venetian plaster aligns well with biophilic design principles, creating a connection to the natural world within your interiors. Embracing Venetian plaster can lead to a calming and serene atmosphere in your living or working space - a direct benefit of its association with nature. The eco-friendliness of Venetian plaster extends beyond its manufacturing process; it is also known for its long lifespan, reducing the need for frequent renovations and minimising environmental impact.

Several factors influence the cost of Venetian plastering, including the type of plaster used, the size of the area to be covered, the complexity of the design, the preparation work required, and the location of the project. Factors like the skilled application of techniques, the use of micro cement in bathrooms, and the involvement of skilled artisans can impact the overall cost due to the craftsmanship involved.

In terms of the type of plaster used for Venetian plastering, the quality and brand can significantly affect the price. High-end plasters often come at a premium compared to more basic options. The size of the area to be covered also plays a crucial role; larger spaces will naturally require more material and labour, impacting the overall cost. Intricate designs and patterns will demand more time and expertise, leading to higher expenses.

Preparation work, such as surface cleaning and priming, is essential for a successful plastering job. The thoroughness of this process can influence the final outcome and cost. The location of the project can also be a determining factor, with urban areas generally having higher labour costs than rural locations. Skilled application of techniques, like burnishing and waxing, adds finesse to the finish but may require additional time and expertise, driving up the cost.

The type of plaster chosen for the Venetian finish plays a significant role in determining the cost. While traditional plasters like Tadelakt offer a luxurious and polished finish, they may come at a higher price point due to the craftsmanship involved. On the other hand, multi-finish plasters provide a more cost-effective alternative while still maintaining a similar aesthetic appeal.

When considering plasters for a Venetian finish, it's essential to factor in not only the visual outcome but also the practicality and durability of the material.

Lime-based plasters are renowned for their eco-friendly properties and breathability, making them ideal for spaces that require moisture regulation. On the contrary, acrylic-based plasters offer a more versatile application and quicker drying time, which can be advantageous for time-sensitive projects.

The affordability and ease of maintenance of each type of plaster should also be taken into account when making a decision.

The size of the area to be covered with Venetian plaster directly affects the overall cost. Larger surfaces such as walls, ceilings, or floors will require more material and labour, leading to higher costs compared to smaller areas. Intricate designs or detailed patterns can further increase the expenses due to the complexity of the application.

For instance, a small accent wall may cost less to plaster in comparison to an entire room. The amount of preparation needed for the surface, like repairing imperfections or applying primers, can also vary based on the size of the area. In terms of larger spaces, contractors often need more time and effort to ensure a consistent finish, adding to the total cost. In contrast, smaller areas might have simpler application processes, resulting in lower expenses.

The complexity of the design in Venetian plastering directly affects the overall cost. Intricate patterns, detailed textures, or unique finishes require more time and skill to execute, resulting in higher costs compared to simpler designs. Factors like layering techniques, colour variations, and custom detailing contribute to the complexity and subsequent pricing of the plastering project.

The intricacy of the design can significantly impact the amount of materials needed for the project. Complex patterns and intricate detailing often require a larger quantity of plaster and pigments, adding to the expenses. Skilled artisans who specialise in executing elaborate designs may charge a premium for their expertise, further enhancing the overall cost of Venetian plastering.

In essence, the more intricate the design, the more resources, time, and skill are required, ultimately reflecting the total cost of the plastering work.

The extent of preparation work required before applying Venetian plaster significantly influences the final cost. Proper surface priming, repair of imperfections, and ensuring a smooth base for application are essential steps that can add to the overall expenses. Factors like the removal of existing finishes, filling cracks, or addressing structural issues can impact the preparation costs.

Preparation work is crucial in Venetian plastering projects as it sets the foundation for a flawless finish. Surface priming not only enhances the adhesion of the plaster but also ensures uniform absorption, resulting in a more consistent look. Repairing imperfections such as dents or uneven surfaces is vital to achieve a polished appearance. Properly preparing the base with the right materials and techniques is key for the plaster to adhere correctly and last longer.

The geographical location of the Venetian plastering project can affect the overall cost due to varying labour rates, material availability, and market trends.

Projects in urban areas like the London region or Surrey may incur higher costs compared to rural locations, reflecting differences in living expenses and demand for specialised artisans. This could be attributed to the higher competition for skilled professionals in bustling cities, leading to increased wages and ultimately impacting the project budget.

Material costs can vary depending on the region's access to specific resources. For instance, a project in an area with abundant local sources of high-quality plaster material may benefit from lower material expenses, while remote locations could face higher transport costs. Market trends also play a significant role, with popular trends in certain regions leading to fluctuations in pricing for Venetian plastering services.

The average cost of Venetian plastering can vary based on different pricing models, including cost per square foot, cost per hour, or cost per project.

Cost per square foot is a common metric used in Venetian plastering projects, providing a straightforward way to gauge expenses based on the area to be covered. On average, this cost can range from £5 to £12 per square foot, depending on the complexity of the design and the quality of materials used.

Alternatively, cost per hour is another pricing model often chosen by contractors for smaller projects or touch-ups. Hourly rates can vary widely, with an average falling between £31 to £55 per hour. This model is beneficial for clients with specific timelines or smaller areas requiring attention.

For larger projects or comprehensive renovations, opting for a cost-per-project approach can provide a more holistic view of expenses. This model factors in all aspects of the Venetian plastering job, including materials, labour, and additional services. On average, total project costs can range from £783 to £3913, depending on the size and scope of the project.

The cost of Venetian plastering per square foot or square metre is a common pricing metric used in the industry. Factors like material costs, labour rates, the complexity of the design, and surface preparation influence this pricing model, with higher square footage often resulting in lower costs per unit compared to smaller areas.

When estimating the cost per square foot for a Venetian plastering project, it's crucial to consider not only the raw materials but also the specialised tools and skilled labour required. The intricacy of the design can significantly impact the pricing, as more intricate patterns or textures may demand higher labour costs.

The condition of the substrate plays a vital role in cost calculations. Uneven or damaged surfaces might require additional prep work, such as smoothing or repairs, leading to increased expenses per square foot. In contrast, well-prepared surfaces may contribute to more straightforward application processes and thus lower costs.

The cost per hour for Venetian plastering services is determined by the skilled application techniques, hourly rates of artisans or contractors, and the complexity of the project.

Hourly rates play a crucial role in estimating the overall budget for a Venetian plastering project. Artisans with extensive experience and specialised training often charge higher rates due to their expertise in applying this luxurious finish. The intricacy of designs and bespoke requirements can significantly impact the time needed for application, directly affecting the cost per hour. Quality craftsmanship and precision are essential when working with Venetian plaster, as any mistakes would require additional time and resources to rectify, leading to increased hourly costs.

The cost per project for Venetian plastering encompasses a comprehensive pricing model that considers all aspects of the project, from material expenses to labour costs and finishing touches. Providing clients with a total cost estimate for the entire project helps in budget planning and ensures transparency in pricing, offering a holistic view of the financial investment required for a Venetian plastering endeavor.

Factors such as the size of the area to be plastered, the intricacy of the design, and the type of finish desired play a crucial role in determining the overall cost of the project.

The level of expertise of the artisans, the quality of materials used, and any preparatory work needed before the plastering process can impact the final price.

It's essential for clients to request detailed breakdowns of costs and clear pricing structures to avoid any misunderstandings or unexpected expenses along the way.

Along with the base cost of Venetian plastering, there are several additional expenses that clients should consider. These include costs related to materials such as lime putty and marble granules, labour charges for skilled application, equipment hire for specialised tools, and expenses associated with finishing and sealing the plastered surfaces.

When budgeting for a Venetian plastering project, it's essential to factor in the costs for high-quality lime putty which forms the base of the plaster, as well as the exquisite marble granules that contribute to the unique texture and finish. Labour charges from experienced craftsmen who possess the expertise to achieve the desired smooth and glossy look are another significant expense. Hiring specialised equipment like trowels and burnishing tools is essential for proper application.

The materials used in Venetian plastering projects contribute significantly to the overall cost. High-quality materials such as lime putty, marble granules, and other natural aggregates are essential for achieving the desired finish. The cost of materials can vary based on quality, quantity, and sourcing, impacting the total expenses of the project.

Aggregates play a crucial role in Venetian plastering, as they not only provide texture but also determine the final look and durability of the surface. Marble granules, for instance, add a luxurious touch and depth to the finish, creating a lustrous effect that is distinctive to Venetian plaster.

Utilising natural materials in the plaster mixture enhances the breathability and moisture-regulating properties of the surface, making it ideal for humid environments. The choice of materials influences the color intensity and variations, adding character and visual interest to the walls.

Labour costs form a significant portion of the expenses in Venetian plastering projects, reflecting the skill and expertise of artisans involved in the application process. Skilled application techniques, craftsmanship, and attention to detail contribute to the labour charges, with experienced artisans commanding higher rates for their specialised services.

Aside from the actual labour hours, the quality of work also significantly influences the final cost. In terms of Venetian plastering, the delicate blending of materials, the impeccable smoothing of surfaces, and the intricate layering of colours all require a keen eye and steady hand. This level of precision and artistry is not only time-consuming but demands a deep understanding of the materials being used. Therefore, skilled artisans with years of experience can demand a premium for their expertise in creating stunning, long-lasting Venetian plaster finishes.

Equipment hire costs may factor into the overall expenses of Venetian plastering projects, particularly when specialised tools or machinery are required for the application process. Hiring equipment such as trowels, mixers, or scaffolding can add to the project costs, necessitating careful budgeting and planning to accommodate these additional expenses.

Using the right equipment is crucial in achieving the desired finish and quality in Venetian plaster applications. Hiring specialised tools ensures that the project progresses smoothly and efficiently, contributing to a professional outcome. The cost of equipment hire must be balanced against the benefits it brings, such as saving on maintenance and storage expenses associated with owning equipment. Having access to state-of-the-art machinery through rentals can enhance the overall efficiency and effectiveness of the plastering process.

The finishing and sealing processes in Venetian plastering projects play a crucial role in enhancing the durability and aesthetic appeal of the final surface. Applying a wax coat, polishing the plaster, or using specialised sealants are common practices to protect and beautify the Venetian finish, adding to the overall expenses but ensuring a long-lasting and visually appealing result.

Finishing and sealing in Venetian plastering not only provides protection but also elevates the overall look of the surface.

By mastering these techniques and choosing quality materials, craftsmen can achieve a luxurious and timeless finish that captivates viewers with its beauty and durability.

Finding a reliable Venetian plastering contractor is essential to ensure the success of your project. Look for professionals with experience in premium finishes like Venetian plaster who have a proven track record in delivering exceptional results. Seeking recommendations from sources like House Design Ideas or industry events like Build: It and Homebuilding & Renovating Shows can also help in identifying reputable contractors for your Venetian plastering needs.

Experience plays a crucial role in the quality of work delivered by a Venetian plastering contractor. Be sure to enquire about the number of years they have been in the industry and the specific projects they have worked on. A contractor with a substantial portfolio showcasing diverse Venetian plastering jobs indicates their expertise and capabilities.

Reputation is another key factor to consider when selecting a contractor for your project. Check online reviews, testimonials, and ratings to gauge the satisfaction level of their previous clients. A contractor with a stellar reputation is more likely to provide exceptional service.

If you're looking to save money on Venetian plastering costs, consider undertaking certain aspects of the project yourself. For DIY enthusiasts, simple preparation work or application tasks can be managed independently to reduce labour expenses. Alternatively, exploring cost-effective options like hiring local artisans can help in finding budget-friendly solutions for your Venetian plastering project.

Another effective way to cut down on Venetian plastering expenses is to source materials strategically. Comparing prices and quality of essential supplies like lime putty, pigment, and wax can lead to significant savings without compromising on the final finish. Researching online tutorials or attending workshops hosted by renowned organisations in the field can equip you with valuable skills and insights for achieving professional-looking results at a fraction of the cost.

Skimming plaster is a technique used to create a smooth and even surface on walls and ceilings.

In this article, we will explore the different types of skimming plaster, such as gypsum, lime, cement, and clay plaster. We will also discuss the various uses of skimming plaster, including smoothing walls, covering imperfections, and preparing surfaces for painting.

Delve into the application process, benefits, and common mistakes to avoid when using skimming plaster. Discover everything you need to know about skimming plaster!

Skimming plaster is a technique used to apply a thin coat of plaster to a wall or surface, creating a smooth and even finish. It is commonly used to improve the appearance of walls by covering imperfections and providing a clean base for painting or wallpapering.

Skimming plaster is a versatile method that can rejuvenate tired walls and transform the overall aesthetic of a room. This technique is particularly effective in concealing cracks, bumps, and uneven surfaces, giving the wall a fresh, pristine look. The application of a thin layer of plaster not only enhances the visual appeal of the space but also serves a functional purpose by ensuring a level and solid foundation for subsequent decorative treatments. Skimming plaster allows for greater flexibility in terms of design choices and helps achieve a professional finish.

Explore further: How To Plaster A Ceiling

Skim plaster comes in various types, including gypsum plaster, lime plaster, cement plaster, and clay plaster. Each type offers unique characteristics and benefits for different applications.

Gypsum plaster is a popular choice due to its smooth finish and easy application. It is composed of gypsum, water, and sometimes additives like perlite for improved strength. This type of skimming plaster is ideal for interior walls and ceilings, providing good adhesion to various surfaces.

Gypsum plaster is a popular choice for skimming surfaces due to its ease of application and smooth finish. It is known for its fast-drying properties and ability to create a uniform base for further decoration.

Regarding mixing gypsum plaster, the process is relatively straightforward. The powder is slowly added to clean water, allowing it to soak, and then mixed thoroughly until achieving a creamy consistency. This ensures a lump-free mixture that is ready for application. Applying gypsum plaster onto walls requires a skilled hand to achieve a smooth and even surface. Utilising the correct tools, such as trowels and hawks, is essential for achieving the desired results.

Lime plaster is a traditional choice known for its breathable nature and flexibility, making it suitable for historic buildings or areas with high moisture levels. It provides a unique finish that adds character to surfaces.

Regarding properties, lime plaster has excellent vapour permeability, allowing moisture to evaporate rather than get trapped within the walls. This helps prevent dampness and mould growth, promoting a healthier indoor environment. In restoration projects, lime plaster is highly valued for its ability to match the original aesthetics, offering a seamless blend with existing structures.

The application process of lime plaster typically involves slaking quicklime, mixing it with water and aggregates, followed by application in layers. Special considerations include ensuring proper cure times between coats and using the right tools to achieve a smooth or textured finish.

Cement render is a durable option often used for exterior surfaces or areas prone to high impact. It provides a strong coat that can withstand harsh weather conditions, making it ideal for outdoor applications.

Its versatility allows for application on a variety of surfaces, including concrete, brick, and even metal. The thickness of the render can be adjusted depending on the surface and the desired finish. Cement render not only offers protection but also adds an aesthetic appeal to buildings. By forming a robust layer, it shields the structure from moisture, preventing damage and decay over time. This type of render is commonly used for walls, ceilings, and even decorative elements.

Clay plaster is an eco-friendly option that offers a smooth and natural finish to walls. It is breathable and regulates indoor humidity levels, creating a healthy living environment.

One of the key benefits of using clay plaster is its sustainable nature. By utilising natural materials, it reduces the environmental impact typically associated with traditional wall finishes.

Clay plaster has excellent thermal properties, helping to insulate homes and reduce energy consumption. The application process of clay plaster involves mixing the clay with water to create a paste, which is then applied to the walls and allowed to dry naturally.

Not only does clay plaster contribute to a healthier interior due to its ability to absorb and release moisture, but it also adds a unique, earthy aesthetic appeal to any space, creating a warm and inviting atmosphere.

Skimming plaster serves multiple purposes, such as smoothing walls, covering imperfections, and creating a flawless surface for painting. It is a versatile technique that enhances the aesthetic appeal of any room.

One significant benefit of skimming plaster is its ability to provide a fresh start for a room's decor. By creating a smooth and even surface, skimming allows homeowners to choose from a myriad of finishing options like painting, wallpapering, or even leaving the texture exposed for a modern look. In-home improvement projects and skimming plaster can revitalise outdated spaces and bring a sense of cohesion to a design scheme. Whether it's disguising old wallpaper seams, repairing damaged walls, or simply updating the look of a room, skimming plaster offers a cost-effective solution for transforming living spaces.

Skimming plaster is commonly used for smoothing walls, especially in rooms where a flawless finish is desired. It helps create a uniform surface that enhances the overall look of the space.

Before starting the skimming process, it's crucial to prepare the walls adequately. This involves cleaning the surface thoroughly to remove any dirt, grease, or loose material that could affect the adhesion of the plaster. Repair any cracks or holes in the wall before applying the skim coat to ensure a seamless and level finish.

When applying the plaster, use a steel trowel to spread it evenly across the wall in a thin layer. Work in small sections, feathering the edges to blend the plaster seamlessly. Sand the surface lightly once the plaster has dried to achieve a smooth and polished look.

The benefits of a smooth wall finish extend beyond aesthetics. In living rooms and bedrooms, smooth walls provide a modern and elegant backdrop for furniture and decor, enhancing the overall ambiance of the space. In kitchens and bathrooms, a smooth finish makes walls easier to clean and maintain, reducing the accumulation of dust and grime.

Skimming plaster is an effective solution for covering imperfections on walls or surfaces. By applying a thin coat of plaster, minor flaws or uneven areas can be concealed, resulting in a seamless appearance.

Common imperfections that can be easily remedied using skimming plaster include hairline cracks, dents, uneven textures, and small bumps. The process of achieving a flawless surface starts with preparing the wall by cleaning it thoroughly and ensuring it is dry and free of loose debris. Next, apply a bonding agent to promote adhesion before evenly spreading the skimming plaster using a trowel in smooth, overlapping strokes. Once dry, sand the surface lightly to remove any excess plaster and achieve a smooth, even finish.

Skim plaster is an essential step in creating a smooth surface for painting. By applying a skim coat of plaster, the wall becomes a perfect canvas for paint, ensuring a professional and polished finish.

When walls are properly skimmed before painting, imperfections and bumps are smoothed out, providing a seamless foundation for the paint to adhere to. This process not only enhances the aesthetic appeal of the walls but also prolongs the lifespan of the paint job. To achieve a flawlessly smooth surface, skilled tradespeople use techniques such as feathering, floating, and sanding to ensure that every inch of the wall is even and ready for painting. It's crucial to prime the surface after skimming to seal and further prepare the wall, maximising the adhesion of the paint.

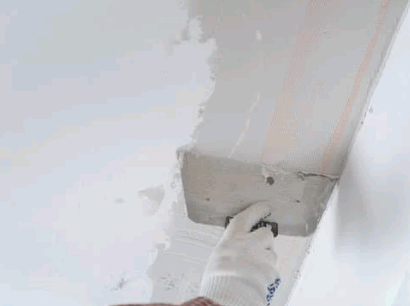

The application of skimming plaster involves several key steps, including preparing the surface, mixing the plaster to the correct consistency, applying the plaster in thin layers, and finishing with sanding for a flawless result.

Surface preparation is crucial for a successful skimming plaster application. Begin by ensuring the area is clean and free from dust, dirt, and debris. Next, use a primer or sealer to create a smooth base for the plaster.

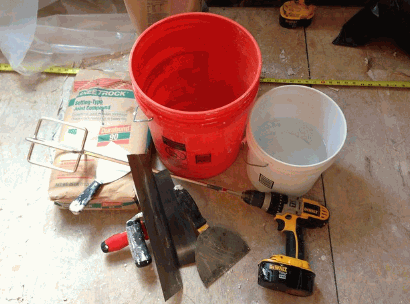

When mixing the plaster, measure the water and plaster powder precisely to achieve the desired consistency. Stir the mixture thoroughly until it is lump-free and uniform.

Applying the plaster should be done gently and evenly in thin layers to avoid buildup and achieve a seamless finish.

Properly preparing the surface before applying skimming plaster is crucial for achieving a successful finish. This step involves cleaning the wall, ensuring it is dry and free from debris, and priming the surface if needed.

It is essential to repair any cracks or imperfections on the surface before beginning the skimming process. Use a suitable filler to level out uneven areas and sand them smoothly for a seamless result.

For painted surfaces, it is recommended to lightly sand the paint to provide a better key for the new plaster. Similarly, if dealing with plasterboard, ensure the joints are taped and filled correctly to prevent any cracking in the future.

Mixing the plaster to the correct consistency is essential for a successful plastering application. The plaster should be mixed with fresh water using the recommended ratio to ensure a smooth and workable mixture.

Usually, the plaster-to-water ratio for plastering is around 4:1, but this may vary depending on the specific product instructions. One method to achieve the right consistency is by gradually adding plaster to water, and stirring constantly to avoid lumps. Using the appropriate tools, such as a mixing paddle attachment for an electric drill or a hand-held mixing tool, can help simplify the process.

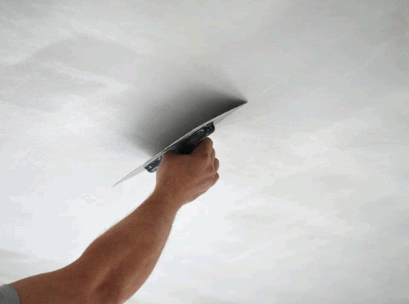

Applying skimming plaster requires a skilled technique to achieve a smooth finish. Using a hawk and float, the plaster is spread evenly in thin layers across the wall surface, ensuring uniform coverage and minimal imperfections.

Consistency in the application process is paramount. It is crucial to maintain a steady pace to avoid uneven build-up or drying patches. By feathering the edges with the float, you can blend each layer seamlessly, creating a seamless surface. Keep the hawk tilted slightly to keep the plaster workable, and rotate it frequently to prevent the mix from setting prematurely. Working in small sections and overlapping strokes will help in achieving a professional-looking result.

Sanding and finishing are the final steps in the skimming plaster process, aiming to achieve a smooth and flawless surface. Sanding helps remove any imperfections or rough areas, while finishing ensures a seamless base for further decoration.

Regarding sanding, it is crucial to use the right tools. Start with a coarse-grit sandpaper to tackle any prominent bumps or uneven spots, then gradually move on to finer grits for a smoother finish. Patience is key during this process to ensure a uniform surface. Once the sanding is complete, apply a primer to seal the surface and enhance adhesion for the final finish.

Skimming plaster offers various benefits, including creating a smooth and even surface, hiding imperfections, and enhancing the aesthetic appearance of a room. It provides a versatile solution for achieving a flawless finish.

Using skimming plaster transforms walls into a seamless canvas that serves as an ideal backdrop for any décor. It not only elevates the overall look of the room but also helps in creating a more visually pleasing environment. The application of skimming plaster can significantly improve the quality of the walls, making them appear brand new. By concealing any blemishes or irregularities, skimming plaster ensures that the final result is polished and professional.

One of the key benefits of skimming plaster is its ability to create a smooth and even surface on walls. This smooth finish adds a touch of elegance to any room and provides the ideal base for various decorative treatments.

A seamless surface achieved through skimming plaster not only enhances the visual appeal of a space but also plays a crucial role in elevating the overall ambiance. Imagine a room with perfectly smooth walls, where light bounces off evenly, creating a subtle glow that transforms the atmosphere. This flawless finish not only complements modern or minimalist decor but also serves as a canvas for a variety of design options.

From sleek wallpaper to intricate stenciling, a smooth wall surface allows for endless creative possibilities, making it a versatile choice for interior aesthetics.

Skimming plaster excels at hiding imperfections on walls, such as cracks, dents, or uneven surfaces. By applying a skim coat of plaster, these flaws are concealed, resulting in a seamless and flawless appearance in any room.

For instance, hairline cracks that can be a common sight on older walls can easily be masked with a layer of skimming plaster, creating a smooth canvas that is ready for painting or wallpapering. Similarly, bumps and dents from previous wall fixtures can be smoothed out entirely, erasing any evidence of prior damage. Even the most subtle irregularities in a wall's texture can be corrected with the application of skimming plaster, ensuring a uniform and pristine surface.

Using skimming plaster can significantly enhance the aesthetic appearance of a room by providing a clean and flawless finish. It allows for greater flexibility in decorating and improves the overall visual appeal of the space.

Skimming plaster creates a smooth canvas that seamlessly blends with various design styles, from minimalist to traditional. This versatility makes it a preferred choice for interior decorators and homeowners looking to achieve a polished look. With its ability to hide imperfections and create a uniform surface, skimming plaster sets the stage for the addition of decorative elements such as mouldings, wallpapers, or paint finishes.

Skimming plaster acts as a foundation that elevates the entire ambience of a room, transforming it from ordinary to extraordinary. Its clean lines and seamless texture provide a modern touch while maintaining a timeless elegance that suits any interior theme.

Several common mistakes can occur when skimming plaster, such as not preparing the surface properly, using the wrong type of plaster, not mixing the plaster correctly, and applying either too thin or too thick layers of plaster.

When skimming plaster, failing to adequately prepare the surface can lead to adhesion issues, resulting in a patchy or uneven finish. To avoid this, ensure that the surface is clean, free of debris, and properly primed before applying the plaster.

Using the wrong type of plaster, such as one not suitable for skim coating, can result in cracking or peeling over time. Be sure to choose a high-quality skimming plaster specifically designed for the task at hand to guarantee a durable and smooth finish.

Incorrectly mixing the plaster can lead to inconsistencies in texture and setting time. Follow the manufacturer's instructions precisely to achieve the right consistency and avoid any setting problems during application.

Applying layers that are too thin may not fully cover imperfections, while layers that are too thick can result in sagging and drying issues. Aim for a consistent thickness across each layer, allowing for proper curing and a flawless end result.

A critical mistake in skimming plaster is not preparing the surface adequately before application. Failing to clean, dry, or prime the wall can result in adhesion issues, uneven finishes, or poor plaster performance.

Surface preparation is crucial in achieving a flawless, professional finish when working with plaster. Without proper preparation, any imperfections on the wall can be magnified, leading to a subpar outcome. To ensure a suitable base for your plaster project, begin by inspecting the surface for any damage, cracks, or imperfections that need to be addressed. Next, thoroughly clean the area to remove dust, dirt, and grease, which can hinder adhesion.

Priming the wall is another essential step; this helps create a uniform surface for the plaster to adhere to, enhancing its durability and longevity.

Selecting the wrong type of plaster for skimming can lead to issues such as poor adhesion, improper finish, or unsuitability for the application surface. It is essential to choose the appropriate plaster type based on the specific project requirements.

Using the wrong type of plaster can create a domino effect of problems in a skimming project. Not only does it compromise the adhesion between the plaster and the surface, but it can also result in an uneven finish that detracts from the overall aesthetic appeal. The compatibility between the plaster and the surface is crucial for a successful outcome.

Incorrectly mixing the plaster can result in issues such as lumps, inconsistent texture, or poor workability. It is crucial to follow the manufacturer's guidelines and achieve the right consistency for a successful skimming application.

Proper mixing of plaster is essential to ensure that the final outcome of the skimming project meets the desired quality standards. Inadequate mixing can lead to a range of problems that may compromise the overall finish and durability of the surface.

One common issue that arises from incorrect plaster mixing is the formation of lumps, which can create an uneven surface texture and affect the aesthetics of the final coat. An inconsistent texture can make it challenging to achieve a smooth and uniform finish during the application process.

Applying skimming plaster in either excessively thin or thick layers can lead to issues such as poor coverage, uneven surfaces, or extended drying times. Achieving the recommended thickness is crucial for a successful skimming finish.

When skimming plaster is applied too thinly, it struggles to cover imperfections on the underlying surface, often requiring multiple coats to achieve a satisfactory result. This not only extends the time and effort needed but also increases the overall cost of the project.

On the other hand, using thick layers of skimming plaster can result in difficulties in achieving a smooth and uniform finish. Thick plaster is more prone to cracking, shrinking, or sagging, leading to a less durable and visually appealing outcome.

To ensure optimal results, it is essential to follow manufacturer guidelines on plaster thickness and application techniques. Working in small sections and maintaining a consistent thickness throughout the project can help achieve a professional and flawless skimming finish.

Plastering a ceiling may seem like a daunting task, but with the right tools and techniques, it can be a rewarding DIY project.

In this comprehensive guide, we will walk you through the process from start to finish. From preparing the ceiling and mixing the plaster to applying it smoothly and finishing off with a professional touch, we will cover all the steps and tips you need to know for a successful plastering project.

Let's get started!

Plastering is the process of applying a smooth, durable, and often decorative coating to walls or ceilings. It involves using a variety of tools and techniques to achieve a professional finish.

This plastering technique has been utilised for centuries, dating back to ancient civilisations where it served both functional and aesthetic purposes. Initially, plastering was done using primitive methods such as clay or mud-based mixtures applied to surfaces. Advancements in technology and materials have led to the evolution of modern plastering practices.

Before applying plaster, proper surface preparation is crucial to ensure adhesion and longevity. This entails cleaning, priming, and repairing any imperfections on the wall or ceiling. Different types of plaster, including lime, gypsum, and cement-based, offer diverse characteristics suitable for various applications.